Compression plate application to oblique fractures

1. Compression plates

Function

The plate produces compression at the fracture site to provide absolute stability.

Application (oblique fractures)

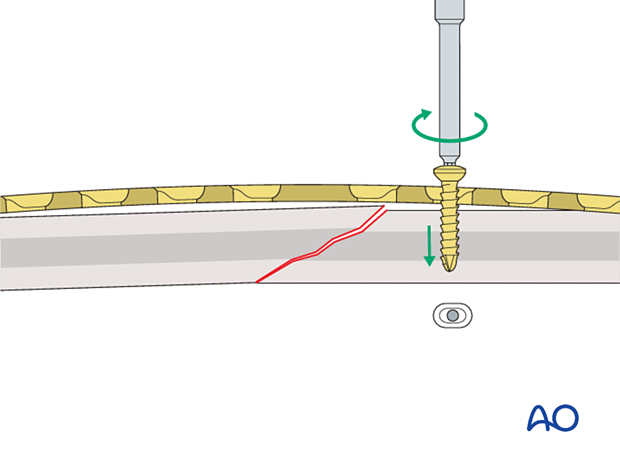

In oblique fractures, place the plate and fix it with one or more screws inserted in neutral mode to create an axilla with one of the bone fragments.

Information about screw insertion in neutral mode is provided here.

This 3D model shows screw insertion in neutral mode.

In oblique fractures, first the plate is placed and fixed with one or more screws inserted in neutral mode into the first fragment.

Application of dynamic compression plate to oblique fractures.

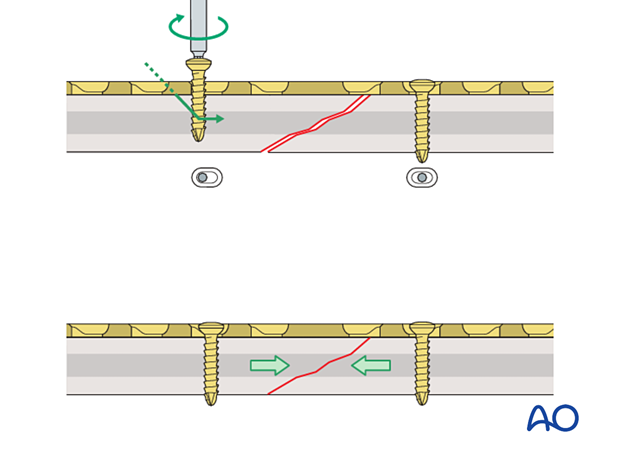

Insert a screw into the second fragment in compression mode. This drives the second fragment into the axilla and compresses the fracture.

Information about screw insertion in compression mode is provided here.

This 3D model shows screw insertion in compression mode.

When inserting a screw in compression mode into the second (mobile) fragment, the fragment is driven into the angle formed by the fracture plane of the fixed (static) fragment and the undersurface of the plate (this is known as the axilla, highlighted in green) and the fracture is compressed.

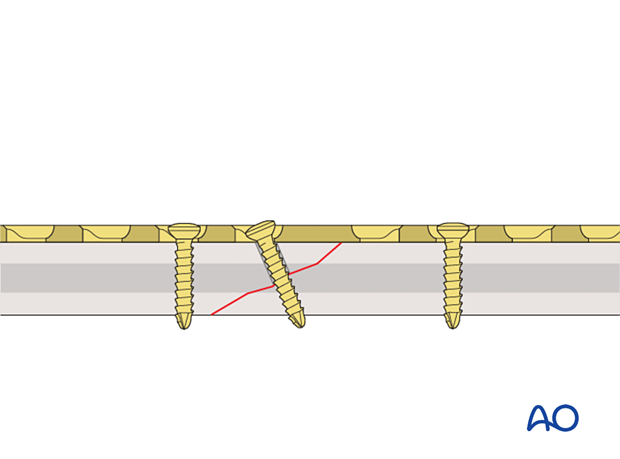

If the plate is applied to an oblique fracture without creating an axilla, the fracture may displace as it is compressed.

If the fracture pattern and location do not allow an axilla to be created when applying the plate, it may be better to apply a lag screw and a neutralization plate.

If the plate is applied to an oblique fracture without creating an axilla then, when a screw is applied in compression mode, the fracture may displace. The apex of the mobile fragment is not "captured" by an axilla.

For the axilla concept to be applied:

- the plate must be orientated so that the direction of applied (compressive) force is co-aligned with the neutral axis of the bone

- the plane of the fracture must be close to perpendicular to the applied force

- the plate should be placed over the apex of the mobile fracture fragment

If the fracture pattern and location do not allow an axilla to be created when applying the plate, it may be better to apply a lag screw and a neutralization plate.

A lag screw can, in some cases, be inserted through the plate to provide additional compression.

Information about lag screw insertion is provided here.

These 3D models show a lag screw with a neutralization plate rotated 90° and aligned with it.

A neutralization plate can reduce the stresses on the lag screw. However, the positioning of the plate has only a minor influence on the screw, as demonstrated by the models.

Here compressive stress is shown in red and tensile stress is shown in blue.