Lag screw principles

1. Introduction

A lag screw is used to compress fracture fragments. It is threaded into the opposite cortex, and slides through a hole in the near cortex. Tightening the screw presses the screw head against the near cortex, compressing the fracture fragments. Optimally, a lag screw should be perpendicular to the fracture plane.

2. Partially threaded and fully threaded lag screws

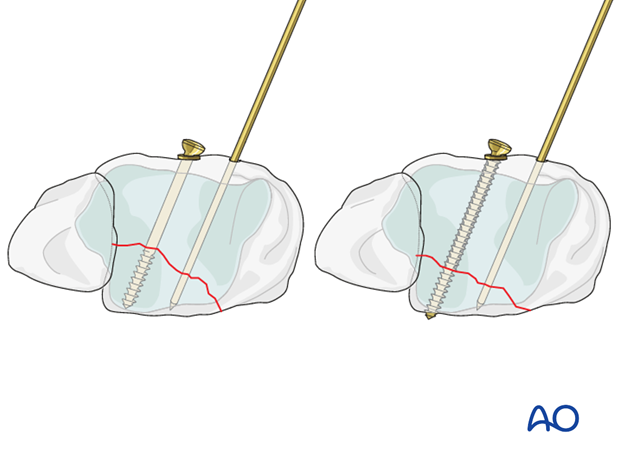

Some screws are designed as lag screws. They are partially threaded so this screw threads into the far cortex, and the smooth shaft slides in the near cortex. The result is the same as if the near cortex were overdrilled.

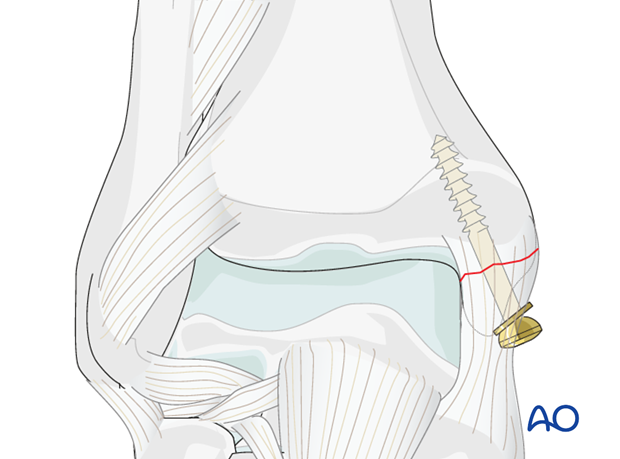

Partially threaded lag screws are often used to compress fractures in cancellous bone. Their threads must lie completely beyond the fracture line to achieve good interfragmentary compression.

3. Glide hole and thread hole

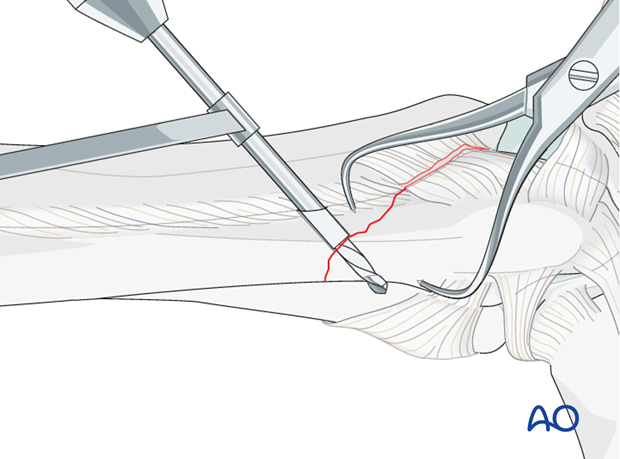

Insertion of a fully-threaded lag screw requires drilling a glide hole in the near cortex, on the same axis as the thread hole in the far cortex.

Glide hole: The cortex under the screw head is drilled to the size of thread diameter so that the thread gets no purchase.

Thread hole: A drill hole which is the same diameter as the core of the screw is drilled, and a tap is used to cut the spiral groove that receives the thread of the screw. The result is a thread hole.

One can drill both cortices with the thread hole sized drill and then overdrill the near cortex. Alternatively, the gliding hole is drilled first, and a drill sleeve is placed within it to direct the drill bit for the thread hole in the far cortex.

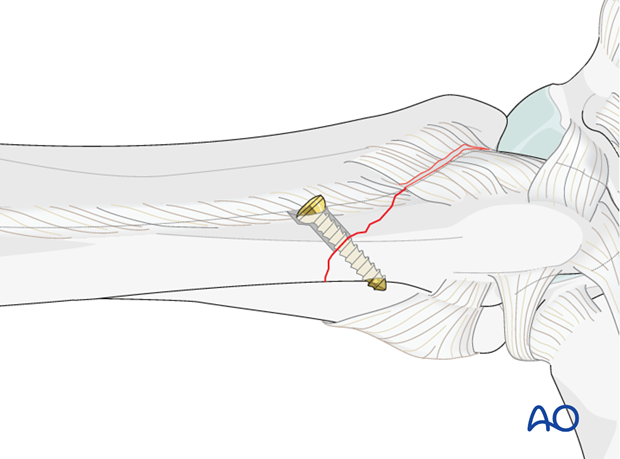

4. Diaphyseal and metaphyseal lag screws

Lag screws can be placed through a plate or outside it. In the latter case, the screw head rests on the bone. A countersink prepares the near cortex to increase the contact area between screw head and bone. It should be used for thick diaphyseal cortex.

In thin metaphyseal cortex, countersinking removes support for the screw head and should not be used. In fact, washers are sometimes advisable to prevent the screw head from sinking.