Choice of implants

1. Introduction

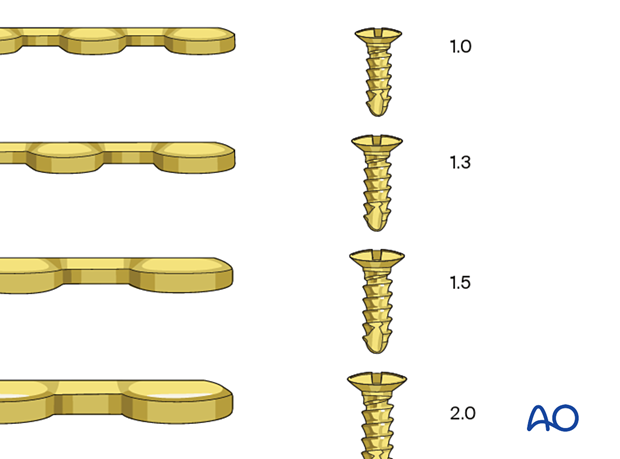

Various implant systems are available to treat midfacial fractures based on the midface system: 1.0, 1.3, 1.5, and 2.0. The numbers refer to the outer screw thread diameter in mm.

These plates are often referred to as “miniplates.”

Plating of the periorbital region is best done with screw thread diameters of between 1.0, 1.3, and 1.5 mm. Low profile plates are recommended, so the patient is not disturbed by implant prominence. However, if increased stability is needed, stronger (thicker) implants must be selected.

Plating of buttresses such as the zygomaticomaxillary buttress (where high masticatory forces are transmitted) requires thicker plates (1.5 or 2.0 mm) than infraorbital rim fractures (1.0 or 1.3 mm).

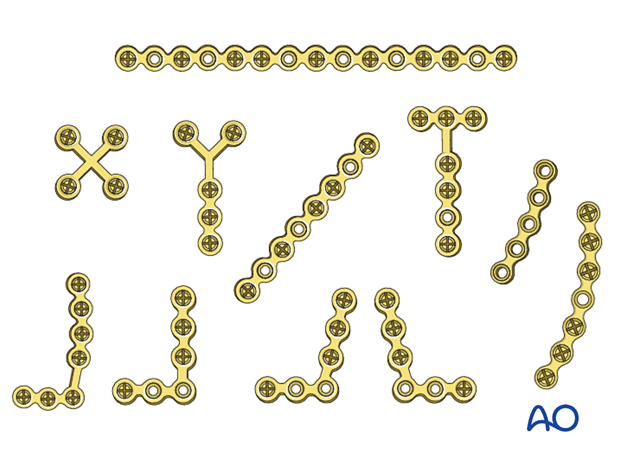

For each of the four screw dimensions, different-shaped plates of various thicknesses are available.

2. Choice of screws

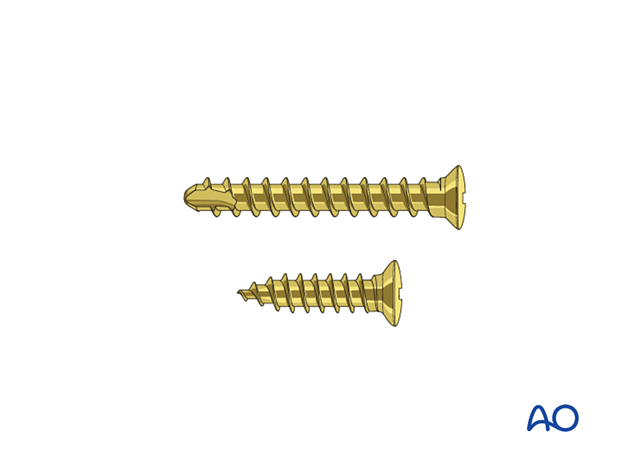

The quality and thickness of the bone determine the choice of screw type. The pitch of the thread is important for anchorage. Most screws used in the midface are self-tapping.

There are two kinds of screws used in the midface:

- Self-tapping (top screw in illustration)

- Self-drilling (bottom screw in illustration)

Self-drilling screws offer the advantage of not requiring predrilling before screw placement. However, with self-drilling screws, a significant amount of force must be applied to engage the screw thread with the bone. This can potentially displace bone fragments.

In general, plates should be fixed with at least two screws in each fracture fragment.

3. Matrix Midface

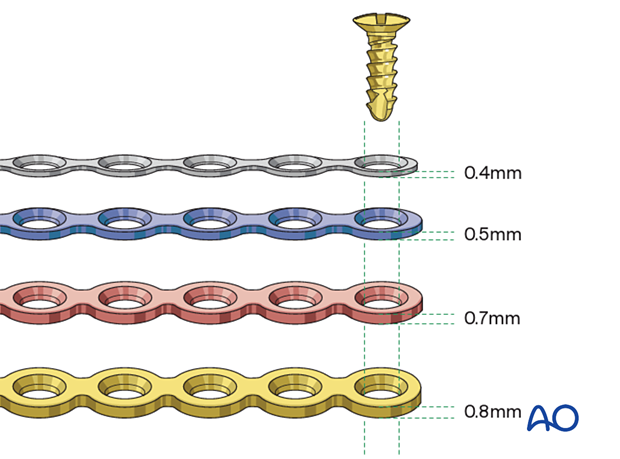

In the Matrix Midface system, only one screw type, with a diameter of 1.55 mm, can be used with plates of varying thicknesses, depending on the specific fixation requirements of each fracture.

The illustration shows the four thicknesses of plates available in the Matrix Midface system. Note that the same screw fits all four plates.

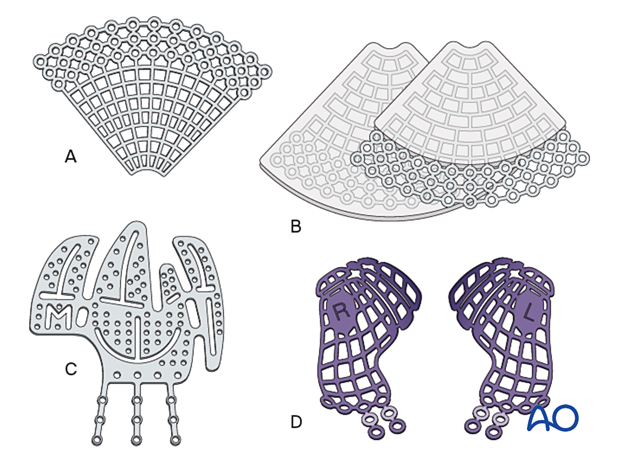

4. Orbital plates

Depending on the size and location of the defect of the orbital walls and orbital floor, reconstruction can be achieved by using implants of various materials and plate/mesh shapes.

The illustration shows a fan-shaped titanium plate (A), a similar plate with porous polyethylene coating (B), a titanium orbital reconstruction plate (C), and preformed anatomic orbital plates (D).

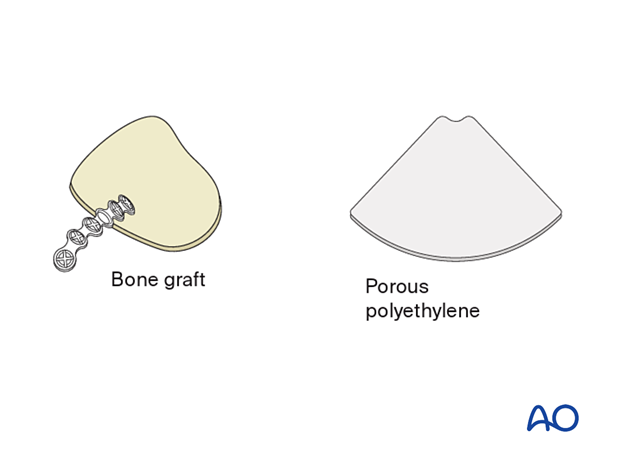

Alternatively, bone grafts or porous polyethylene implants can be used.

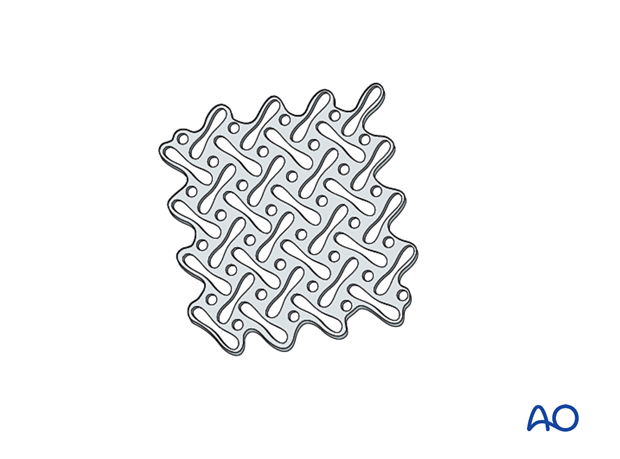

5. Meshes

In non-load-bearing defect zones of the midface (typically maxillary sinus walls), bridging and restoration of the defect area with 3D mesh may be appropriate.

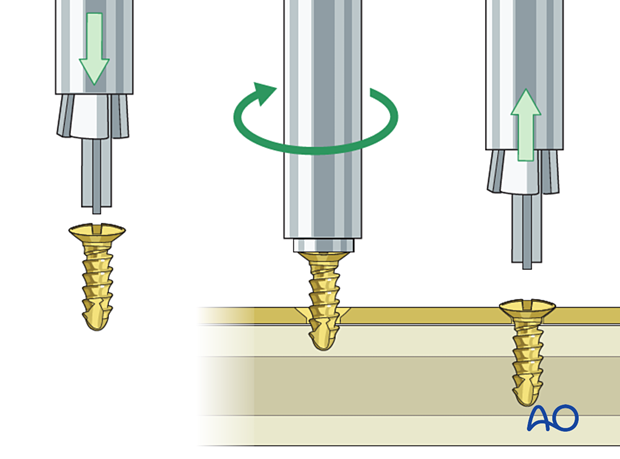

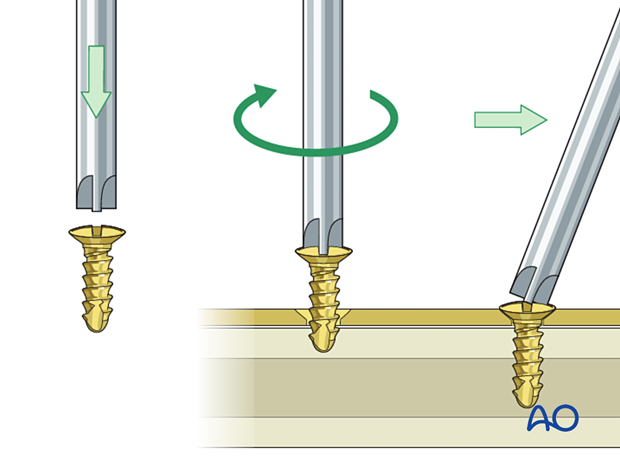

6. Types of screwdriver

Bone thickness varies significantly in the midface. In the thin bones of the NOE area, screw insertion with self-retaining screwdrivers may be problematic due to the force required to uncouple the screwdriver from the screw head after screw insertion.

Therefore, screwdrivers with holding sleeves may be preferable. The choice of screwdriver is made according to surgeon preference.