Locking plate principles

1. Locking versus nonlocking plates - Advantages of a locking plate/screw system

There are several advantages to a locking plate/screw system:

- A locking plate does not have to precisely contact the underlying bone in all areas. When screws are tightened, they “lock” to the threaded screw holes of the plate, stabilizing the segments without pulling the bone to the plate. Locking screws make it impossible for screw insertion to alter the reduction. Nonlocking plate/screw systems require a precise adaptation of the plate to the underlying bone. Without this close contact, tightening of the screws will pull the bone segments toward the plate, resulting in loss of reduction and possibly the occlusal relationship.

- Locking plate/screw systems do not disrupt the underlying cortical bone perfusion as much as conventional plates, which compress the plate to the cortical bone.

- Screws are unlikely to loosen from the plate. Similarly, if a bone graft is screwed to the plate, a locking screw will not loosen during the phase of graft incorporation and healing. The possible advantage of this property of a locking plate/screw system is decreased risk of inflammatory complications due to hardware loosening.

- Locking plate/screw systems have been shown to provide more stable fixation than conventional nonlocking plate/screw systems.

The disadvantage of locking screws is that a surgeon might not realize that the holes have been over-drilled because the head of the screw locks into the plate.

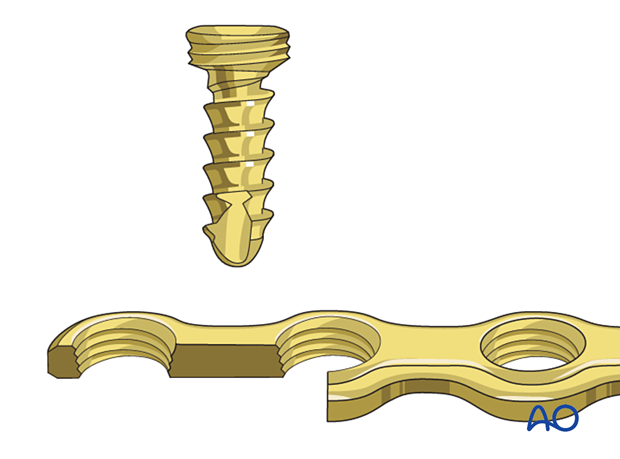

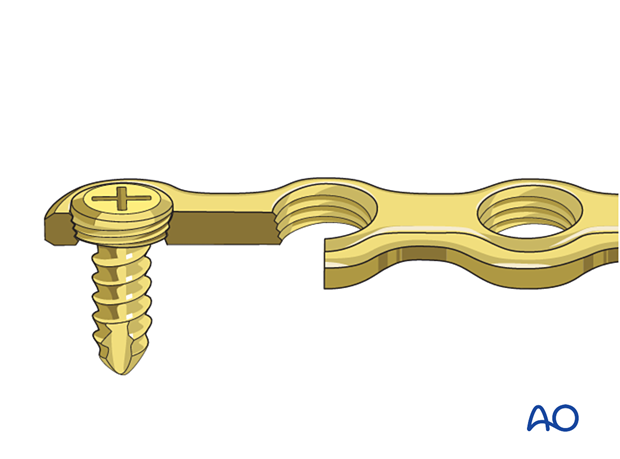

2. Design

Locking screws

The locking plate has threaded plate holes.

Note that the screw heads are also threaded, unlike conventional nonlocking plate/screw systems.

During insertion, the threaded screw head engages and locks into the threaded plate hole.

These 3D models show the insertion of a locking screw (top panel) and a conventional screw in neutral mode (bottom panel).

The conventional screw is inserted in neutral mode and pulls the plate against the bone. Locking screws engage in the plate using the threads and therefore the plate is not pressed against the bone.

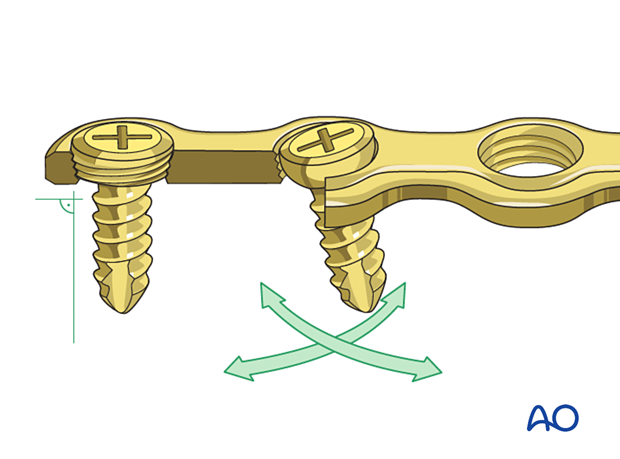

Nonlocking screws

The threaded plate hole also accepts nonlocking screws, which permits angulation, when necessary.

These 3D models allow bending of locking screws and conventional screws to be simulated.

The fixed angle locking construct (bottom panel) provides considerable stability and there is bending of both the screw and the plate. In contrast, the conventional screw (top panel) can freely rotate in its plate hole without causing deformation.

High stress is shown in red and low stress is shown in green.

3. Biomechanics

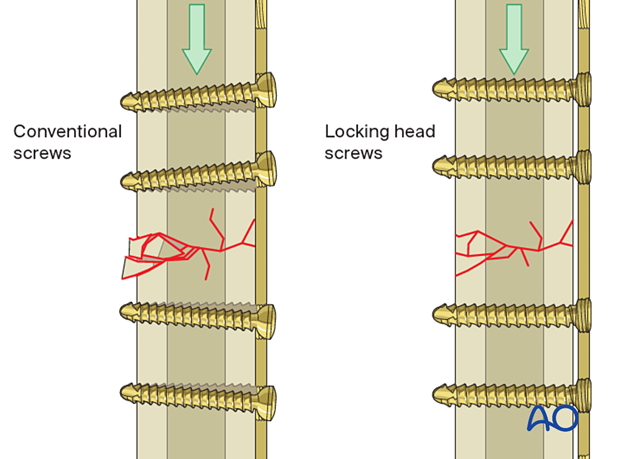

Conventional screws

With the conventional technique, the tightening of the screws draws the plate against the bone. Tightening the screws "lags" the bone to the undersurface of the plate.

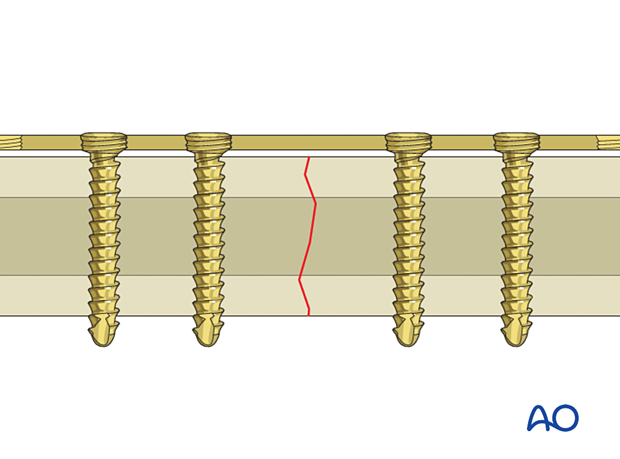

Locking screws

Locking screws are engaged in the plate, and the plate is not pressed against the bone. This reduces interference of the blood supply to the bone underneath the plate.

The tightening of conventional screws (top panel) pulls the plate against the bone. With this technique, the screws "lag" the bone to the undersurface of the plate. This is shown in the top panel.

Locking screws engage in the plate and therefore the plate is not pressed against the bone. This is shown in the bottom panel.

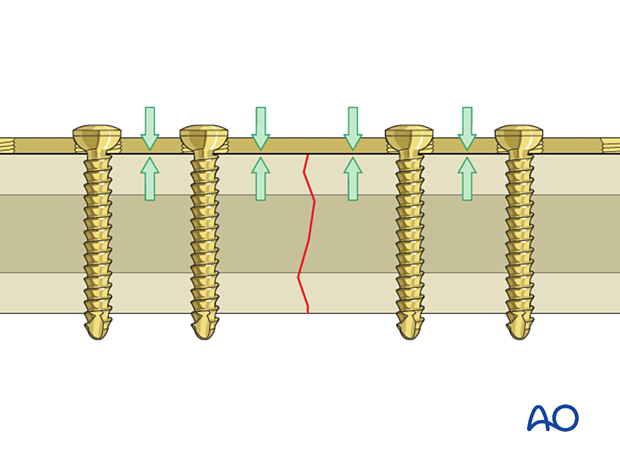

Construct stability: axial loading

The locking plate/screw system provides adequate rigidity and does not depend on the underlying bone buttressing.

On each side of the fracture, the screws are locked into the plate and the bone. The result is a rigid frame construct with high mechanical stability (internal-external fixator).

The impact of axial loading on construct stability is shown here.

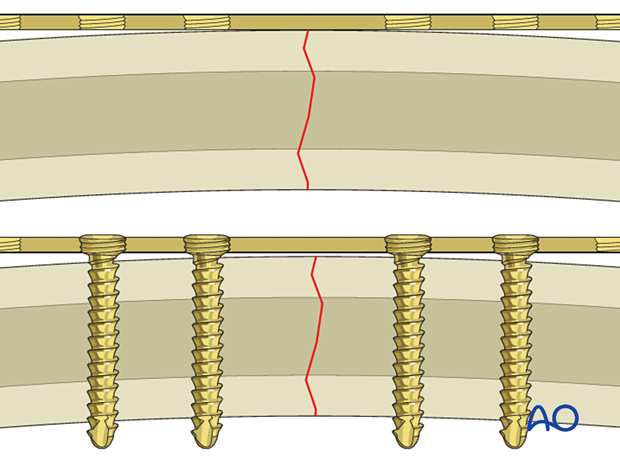

In non-locking plate systems (top panel), rigidity depends on friction between bone and plate. When an axial load exceeds the friction force, the plate will shift the screw head, leading to toggling and loss of stability.

In a locking system (bottom panel), screw loosening rarely occurs because the screw head is locked to the plate, resulting in a rigid frame construct with high mechanical stability (internal-external fixator).

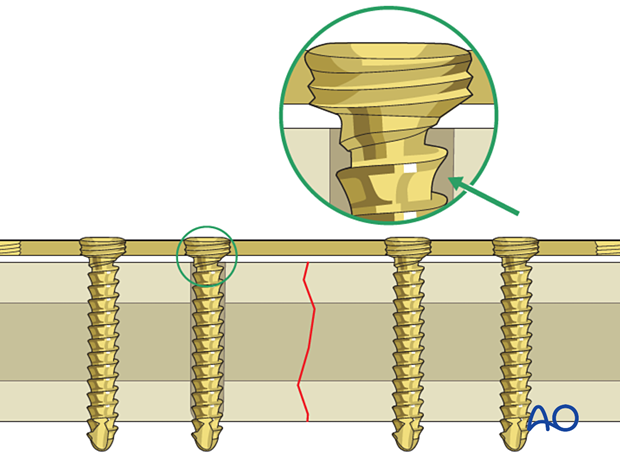

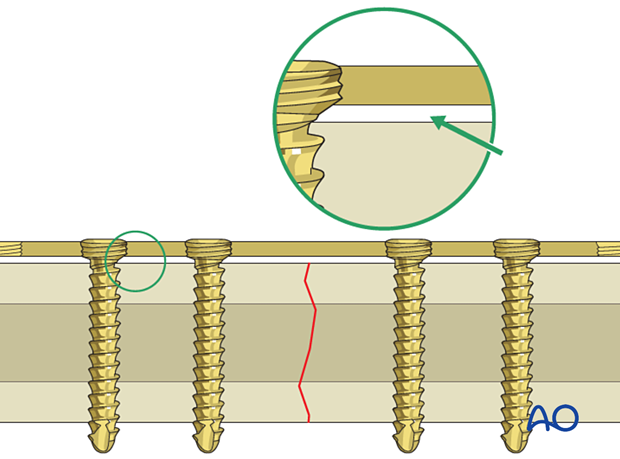

4. Primary loss of reduction

Nonlocking plate system

If a nonlocking plate and screws are used, the plate must be precisely adapted to the bone. Otherwise, tightening the screws may pull the bone to the plate, causing malreduction.

Locking plate system

If a locking plate and screws are used, the plate does not have to be precisely adapted to the bone. When tightening a locking screw, the screw will not cause a primary loss of reduction because it locks into the threaded plate hole and will not draw the bone fragments to the plate.

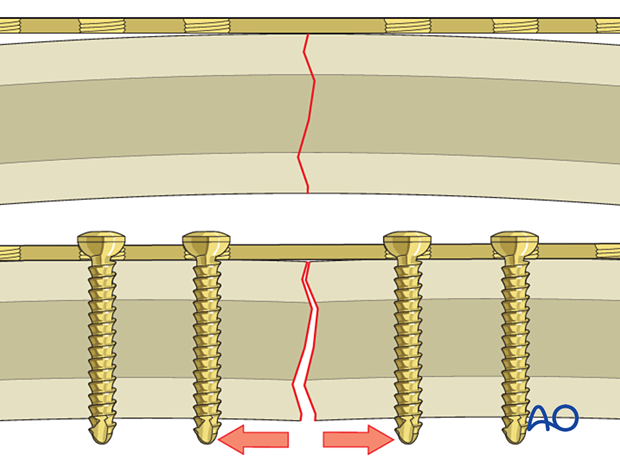

The upper panel shows a non-locking plate and screws. When the screws are tightened the bone is pulled toward the plate, causing malreduction.

The lower panel shows a locking plate and screws. When the locking screw is tightened it does not cause a primary loss of reduction as it tightens into the threaded plate hole and does not draw the bone fragments to the plate.

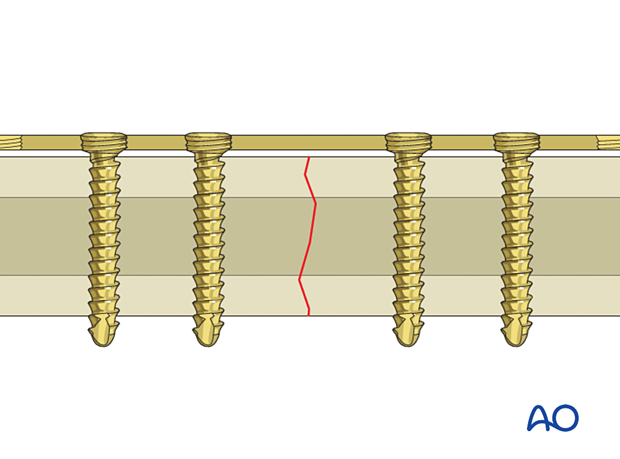

5. Secondary loss of reduction

Nonlocking plate system

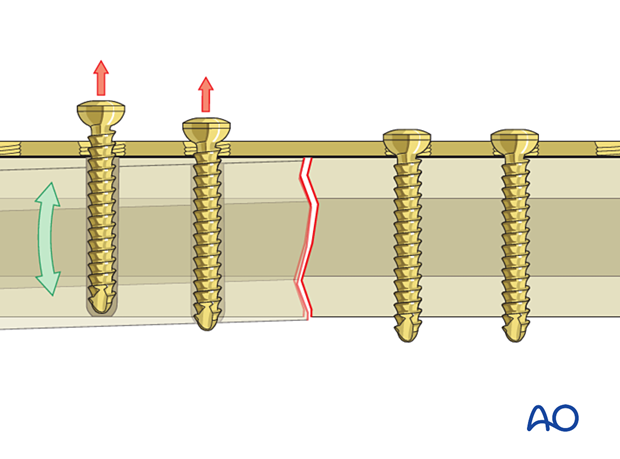

In nonlocking plate systems, screw loosening may lead to loss of reduction.

Locking plate system

In a locking plate system, screw loosening rarely occurs because the screw head is locked to the plate.

One disadvantage of a locking screw system is that if the hole has been over-drilled, the screw head will engage in the threaded plate hole and become locked to the plate. The surgeon may not be aware that the screw threads in the bone lack purchase.